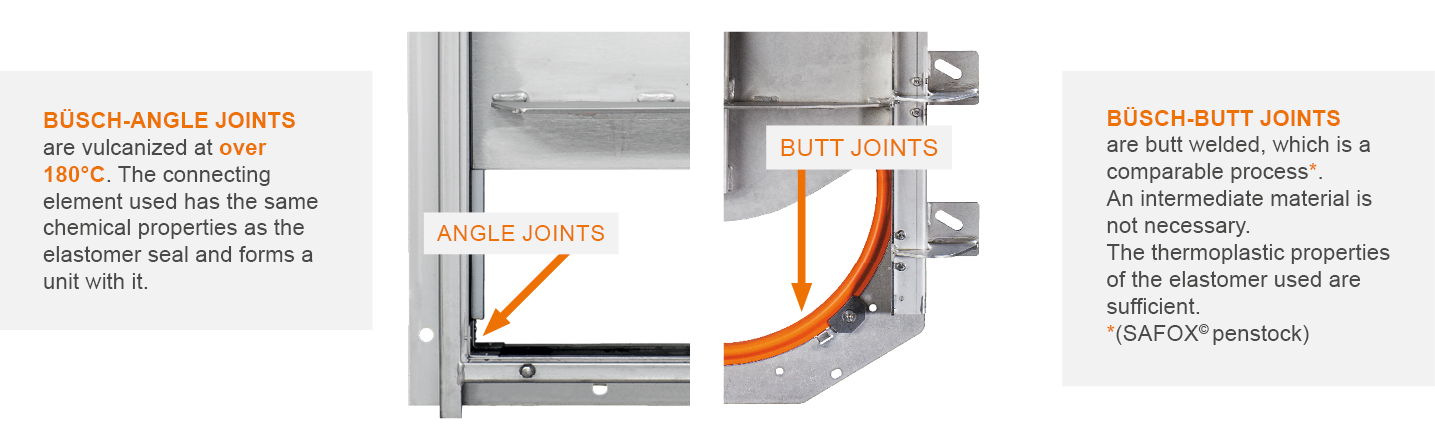

Vulcanizing instead of adhesive bond BÜSCH UNO angle and butt joints

Standard "Hydraulic Steel Construction DIN 19704-2"

Part 2: Structural design and manufacture

Point 6.4 - Seals made from elastomers

„…joints of seals are ... hot to vulcanize."

WHY 180°C?

Hot vulcanization usually occurs at a temperature of 120°C to 160°C.

Our sealing joints (EPDM or NBR) are processed at 180°C to achieve an even better result.

This creates a strong, clean and homogeneous bond. It has permanently elastic properties, high tensile strength, elongation and resistance to ageing and weathering.

Compliant with standards = Vulcanization and butt welding of the sealing joints

GUARANTEED DURABILITY OF THE SEALS

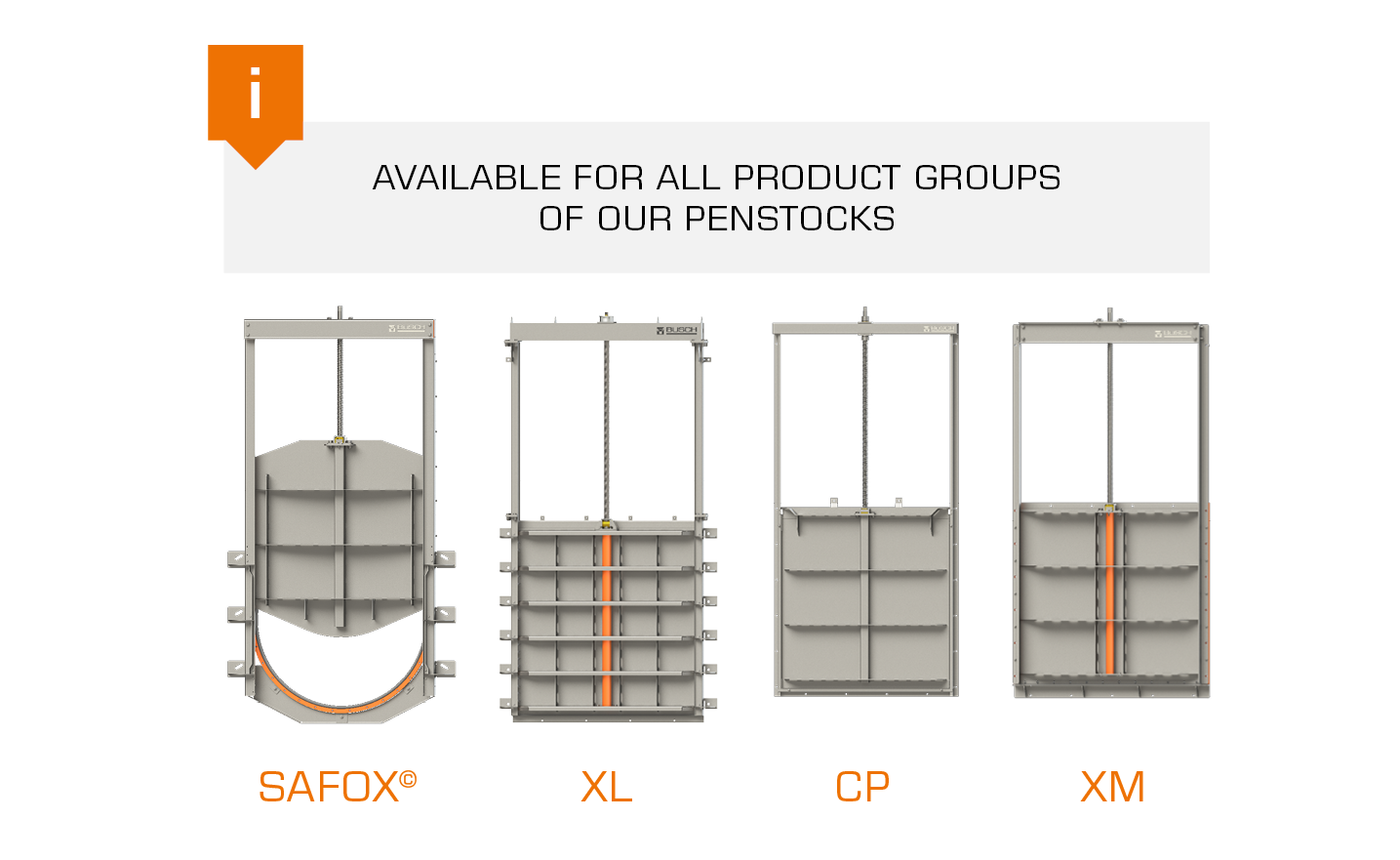

Highest quality for penstocks

BÜSCH UNO | Adhesive bond |

|  |

| + Identical material properties | - Unflexible adhesive layer connection |

| + Identical strength | - High susceptibility to cracks |

| + Identical expansion | - Increased risk of joint leakage |

| + Identical elasticity | - Unproven long-term stability |

| + No risk of joint leakage | - Joint quality dependent on the manufacture |

The BÜSCH UNO sealing joints have the same chemical composition and resistance as the elastomer seal and form a single unit after vulcanization = much more durable! | Adhesive bonds are always independent of the residual material and remain an independent component: The adhesive bond is always a separate component in the elastomer seal. |

Standard "Wastewater treatment plants Construction principles for structures and technical equipment DIN 19569-4"

Part 4: Special design principles for penstocks without housing

Point 6.2 – Special design features

6.2.1 Seals

6.2.1.1 Sealing between frame and plate

„…connections between elastic seals (joints, also in corners) must be hot vulcanized or similar.“

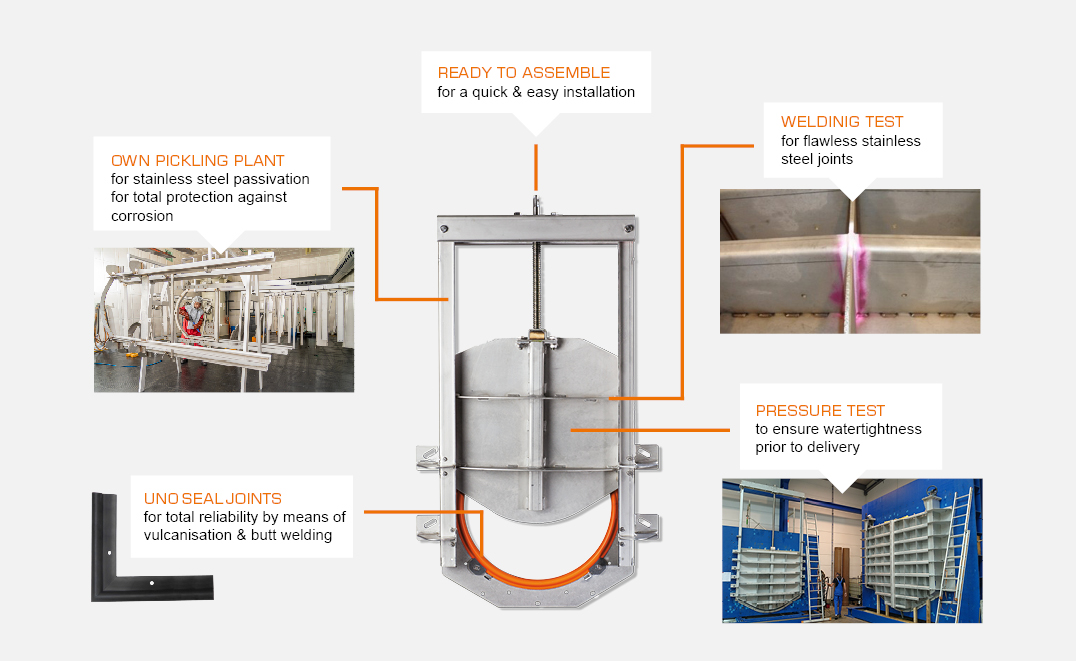

Our pledge of quality: durable NO leakage on BÜSCH UNO angle and butt joints!

WATER PRESSURE TEST IN OUR OWN FACTORY

to ensure tightness before delivery

We test the ready-to-fit penstocks for complete tightness on our in-house pressure test wall.

Your advantages:

+ Seal corpus 100% pressure tested

+ Pressure test: opening size 3000 × 3000 mm & up to 40 mwc (other mwc/sizes on request)

+ Test report & certificate according to 3.1 EN 10204 on request

For further information, please contact your project manager.